Our core competence lies in integrating material expertise, precision processing, and innovative R&D.

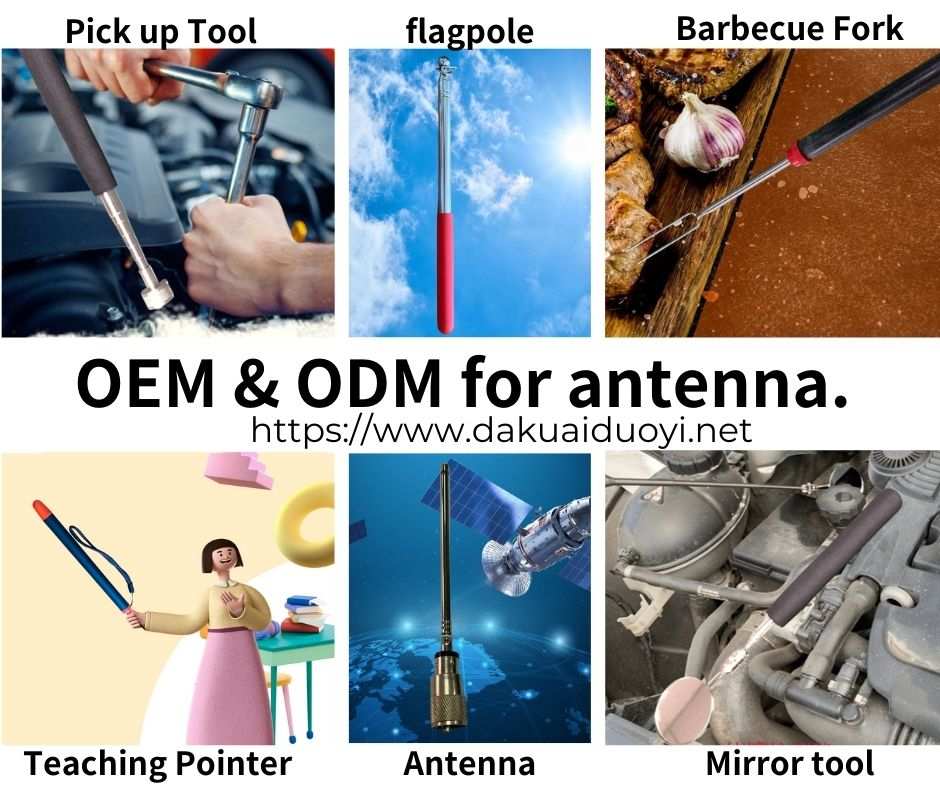

- Manufacturing Engineering Department: Built on years of experience in stainless steel and copper tube production and processing, focusing on stable production and customized telescopic poles and related components. Production lines include automated cutting, tube reduction/expansion, beveling, sealing, shaping, specialized punching, BNC slot milling, and embossing/knurling, with custom jigs and process parameters developed as needed to ensure dimensional accuracy and smooth assembly. Size capability covers diameters from 0.5–19 mm and thicknesses from 0.15–0.5 mm, suitable for telescopic applications including antennas, inspection tools, magnetic pickup tools, teaching pointers, and BBQ forks. We provide end-to-end services: material selection → process design → prototyping → mass production → customized packaging and logistics, accommodating both small-scale trials and stable mass production to meet diverse OEM/ODM requirements.

- R&D & Marketing Department: Focused on material applications, patented structure design, and mold development, delivering customized solutions from concept to mass production. Through digital marketing and international collaboration, we expand global brand presence and co-create value with clients, fulfilling the promise of “Your Idea, Our Creation.”

requirements.